The Green Gas Support Scheme (GGSS) takes government support for net zero up a level and picks up from where the Renewable Heat Incentive (RHI) scheme for biomethane left off. It encourages renewable generators to inject directly into our national gas grid to help tackle one of the biggest barriers to hitting our legally binding target – heat for buildings.

hitting our legally binding target – heat for buildings.

Who is the GGSS for?

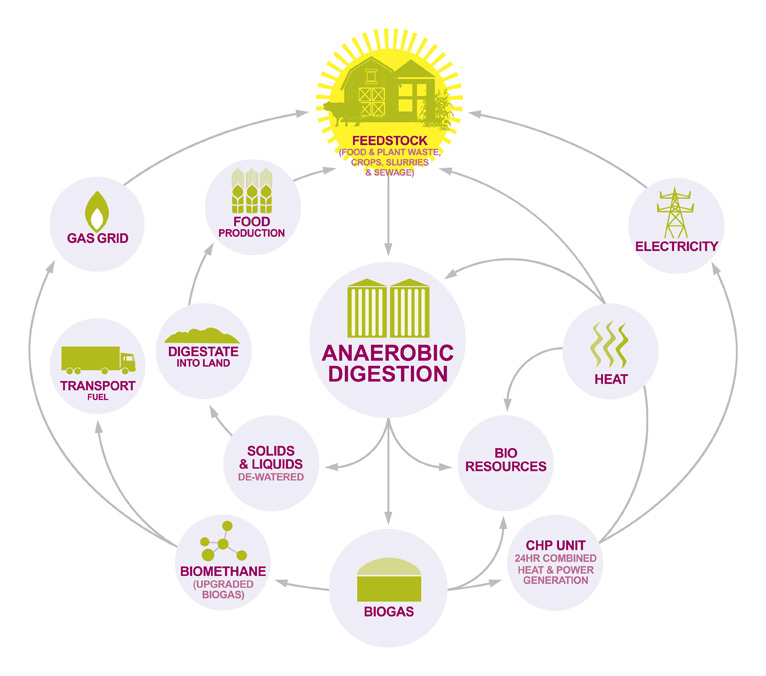

The GGSS has been set up to help new Anaerobic Digestor (AD) plants inject biomethane into the grid. To be viable, the site must be close to the gas grid (if not, building a long pipeline is most likely not feasible). The gas grid must have the capacity to accept the gas in that area. GGSS participants on the scheme will receive quarterly payments for 15 years.

How much is the upgrade in a typical system to inject biomethane?

The GGSS regulations require all sites seeking accreditation to be new. However - for reference, the gas upgrader and grid entry unit would probably set you back £1-3M depending on size etc.

What percentage of grid gas could be biogas in the future?

Ofgem is only expecting to receive 45-90 GGSS applications between 30 November 2021 and 30 November 2025, when it will close to new applicants.

Any other thoughts?

A Gas to Grid site can be accredited under both the Renewable Fuel Transport Obligation (RTFO) and GGSS schemes simultaneously

What's the case for AD?

Micro AD for biogas production for heat and/or electricity generation might be capable of dealing with 0.5-2.5 tonnes of feedstock per day. Micro-ADs (as with all ADs) can run off farm-wastes like manure, animal slurry, or food waste, but they don’t need to be farm based:

- A micro-AD would usually be fitted with a small CHP engine (ranging between 24kWe and 60kWe in size), to produce heat and electricity.

- We don’t see many micro-ADs but they’re increasing in popularity on dairy and poultry farms.

- £150k – 400k CAPEX ballpark, depending on size and complexity Small AD (biogas production for heat and/or electricity generation).

A small AD is a site with one or small two digesters fed with 50-100t of feedstock a day, and a small CHP engine (250-499kWe) producing heat and electricity:

- AD of this size would normally not have any biomethane upgrading technology, because it generally won’t make financial sense.

- £1M-5M CAPEX ballpark, depending on size and complexity Large AD (biogas production and clean-up, with biomethane injection – key to applying for GGSS).

AD plants designed to produce biomethane tend to be large commercial operations which require 150-300 tonnes of organic feedstock each day. They can run off a single feedstock like maize or rye but usually they have a more diverse feedstock mix – typically combining 6-12 feedstocks in total:

- AD plants with biomethane upgraders will normally produce 500-2000m3 of biomethane every hour.

- £10M-15M CAPEX ballpark, depending on size and complexity.

For more information and guidance please give me a call on 024 7669 6512.